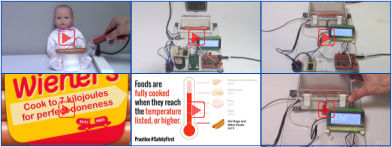

Line-voltage based

hot dog cookers show how NVE components can be used for applications such as power

conversion, battery charging, and motor control. Hot dogs let us see and hear

power transfer.

We start with a bare hot dog directly connected to line voltage, and step-by-step

add safety and cooking enhancements.

Here is a playlist with the six demonstrations:

Uncontrolled

Uncontrolled

We show an uncontrolled, inherently dangerous

hot dog connected directly to line voltage.

Isolated FET control

Isolated FET control

A controlled version uses DC to power the hot

dog via a silicon carbide FET. We use an isolated FET driver and an isolated DC-to-DC

convertor to generate the gate-drive voltage. These circuits are extensible to

H-bridges. We added an electrical box for the hot dog.

Rectified AC

Rectified AC

We eliminated the filter capacitor and used rectified

AC. This prevented startup surges and improved safety.

Temperature sensing

Temperature sensing

Next, we added a temperature sensor to ensure

the hot dog is cooked to a safe temperature. We used an isolator between the SPI

Smart Sensor and the controller because the sensor is in contact with the hot

dog and therefore in contact with high voltage. The isolator also functions as

a level shifter between the 3.3-volt sensor and a five-volt Arduino. The sensor

allowed us to cook to the USDA-recommended 140 °F.

Current sensing

Current sensing

A noncontact current sensor provides overcurrent

detection for improved safety. These sensors are high speed and inherently isolated.

The sensor also allowed a cooking algorithm based on total applied energy, so

we cooked hot dogs to a perfect 7 kilojoules.

Interlock switch

Interlock switch

Finally, we add a GMR Switch and a magnet on the

cover to form an interlock, allowing power to be removed when the cover is open.

GMR Switches are ideal for this type of proximity sensing.

Schematic

The complete hot dog cooker schematic is here: